Dual HS 130 (1224) record player repair and detailed restoration

Written by Bastian Raschke.

Published 2021-04-25 in the category Retro.

I got an old but beautiful Dual record player (1224) in a HS 130 body with integrated 6W amplifier from my dad and repaired/restored the device to have it fully working again. It had some typical issues but the overall quality and maintainability of the device from 1978 is impressive to me compared to modern devices.

Here you see the fully working unit:

Overview

Repaired:

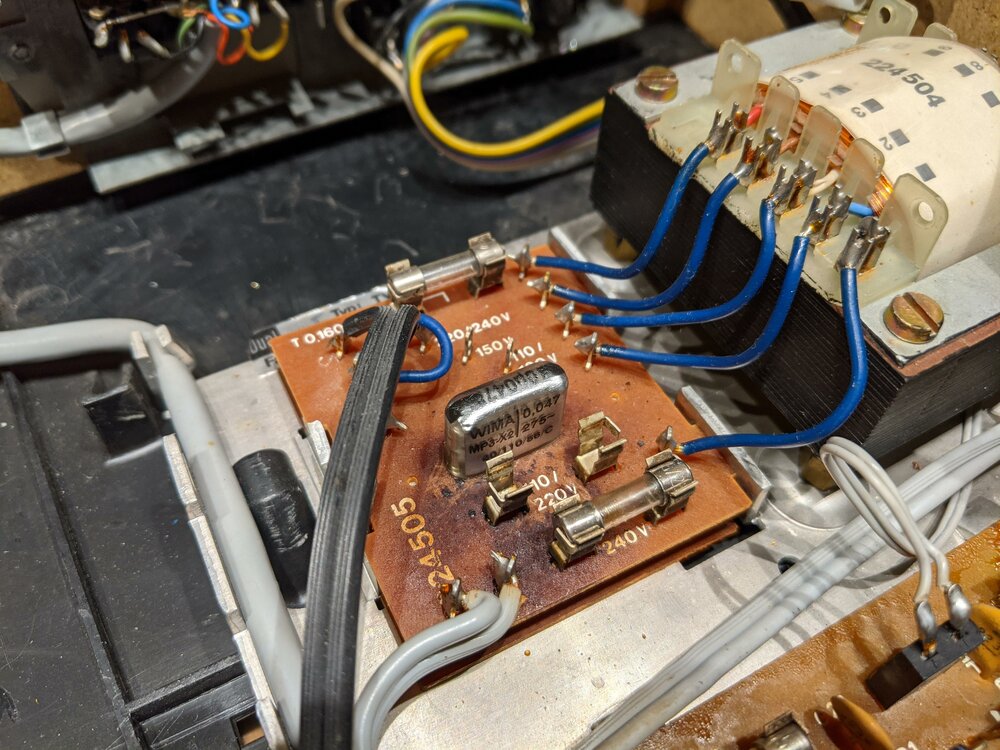

- Replaced the exploded Rifa anti-interference capacitor on mains input side

- Replaced the broken “Steuerpimpel” with silicone tube

- Replaced the cracked “Kurvenrad” with 3D printed replacement part

- Reinforced the cracked height lever of the ton arm with aluminium

- Replaced the broken knob indicators with 3D printed replacement parts

Restored:

- Moved the mains input fuse from 220V to 240V slot

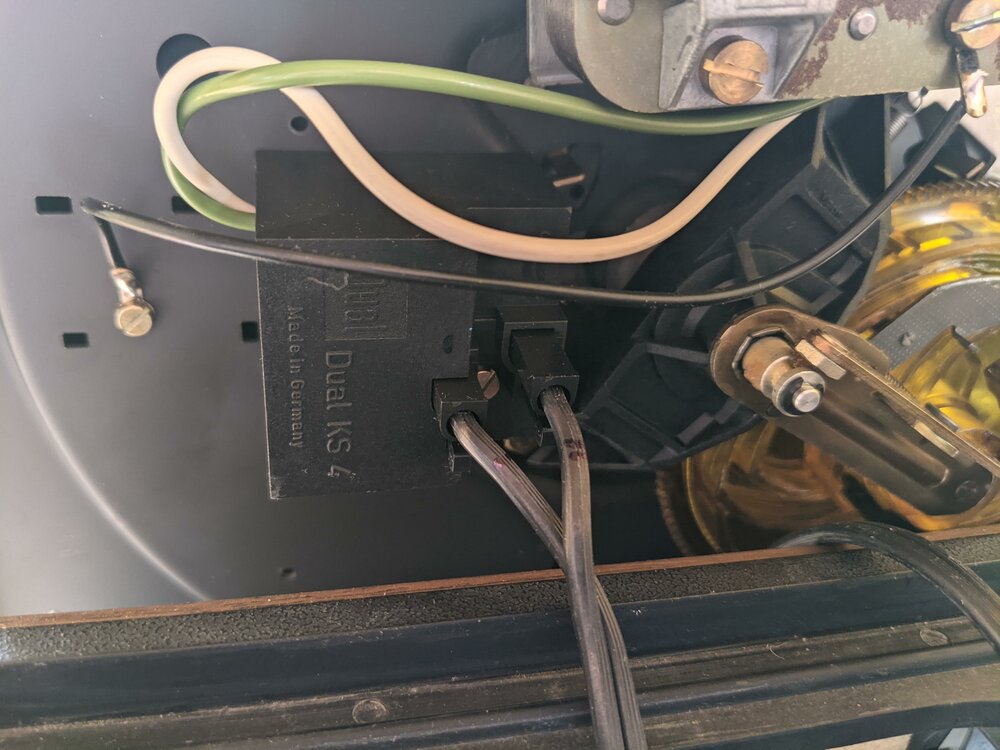

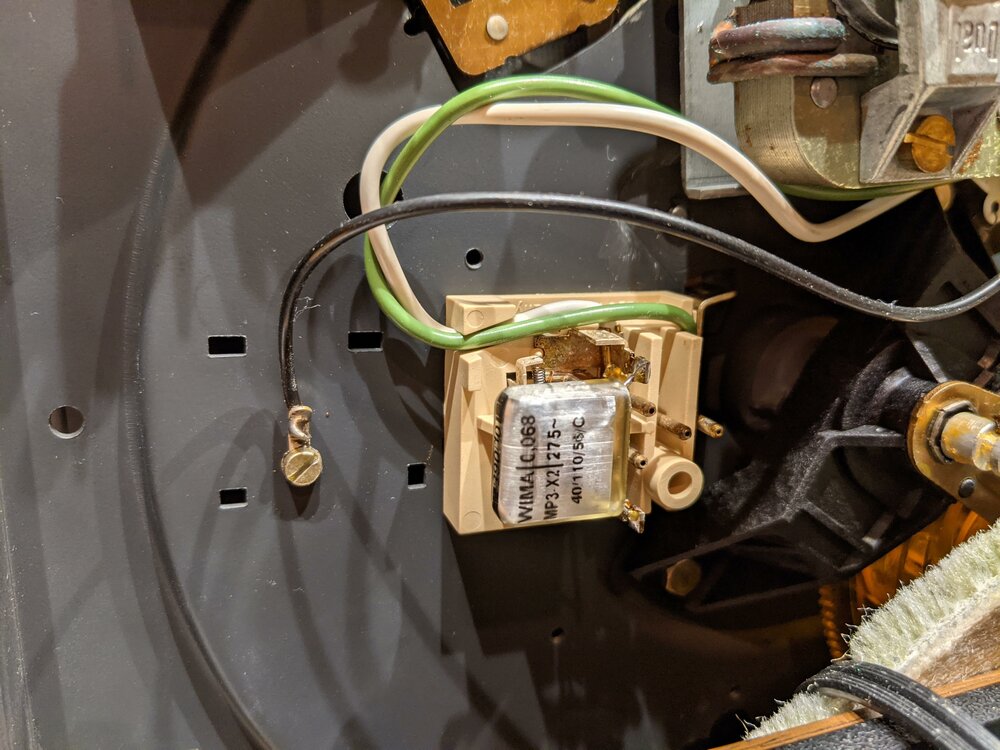

- Replaced also the other Rifa anti-interference capacitor of the motor as a precaution

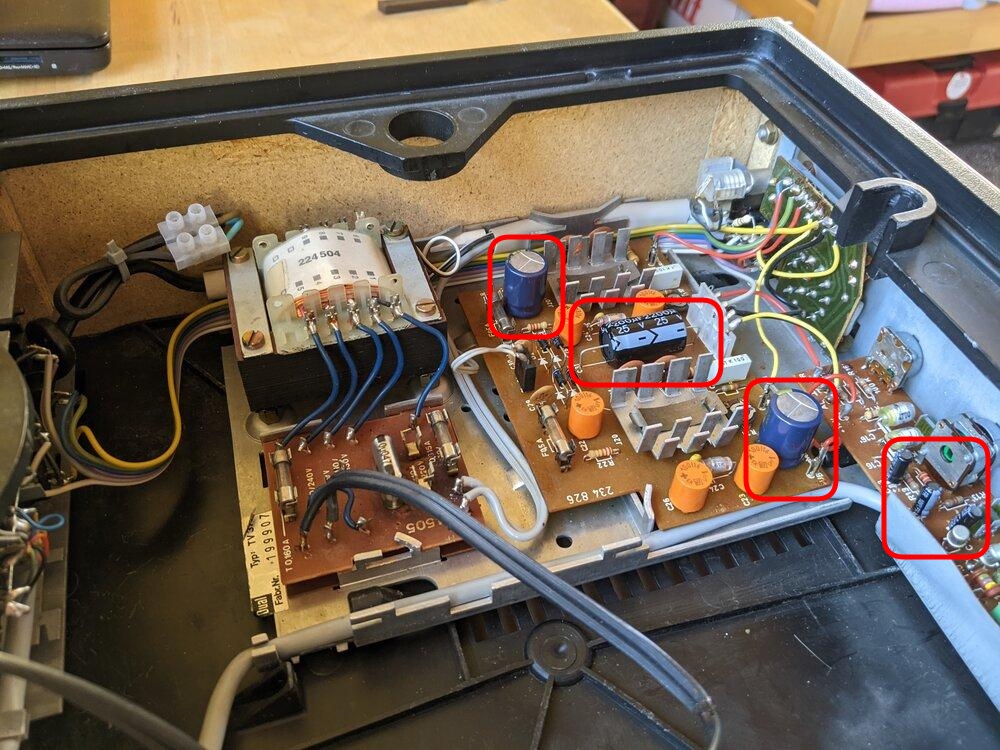

- Replaced most electrolyte capacitors as a precaution

- Replaced the old mains wiring with a new wire as a precaution

- Cleaned the complete device (inner and outer side)

- Applied new grease and oil to moving parts

- Replaced old adhesive under the turntable

Details

Replaced electronics

I replaced both Rifa “time bombs” (the main one was already exploded and released the nasty liquid all over the PCB) and most of the electrolyte capacitors as a precaution (they simply lose their capacity over time in best case or tend to inflate or explode in worst case):

The “Steuerpimpel”

Basically in all old Dual record players with automatic start/stop functionality of that time, the plastic material of that part totally disappears. As a result, the automatic functionality does not work anymore (the arm doesn't move). But the fix is really easy and cheap. I just used a small silicone tube with the following dimensions:

- Diameter (outer): 5mm

- Diameter (inner): about 1,8mm

- Length: 6mm

Note: It is important to use silicone and not some hard plastic because it need to be soft and a bit “sticky” to archive the required friction to move the arm.

After that fix, the automatic worked again like a charm.

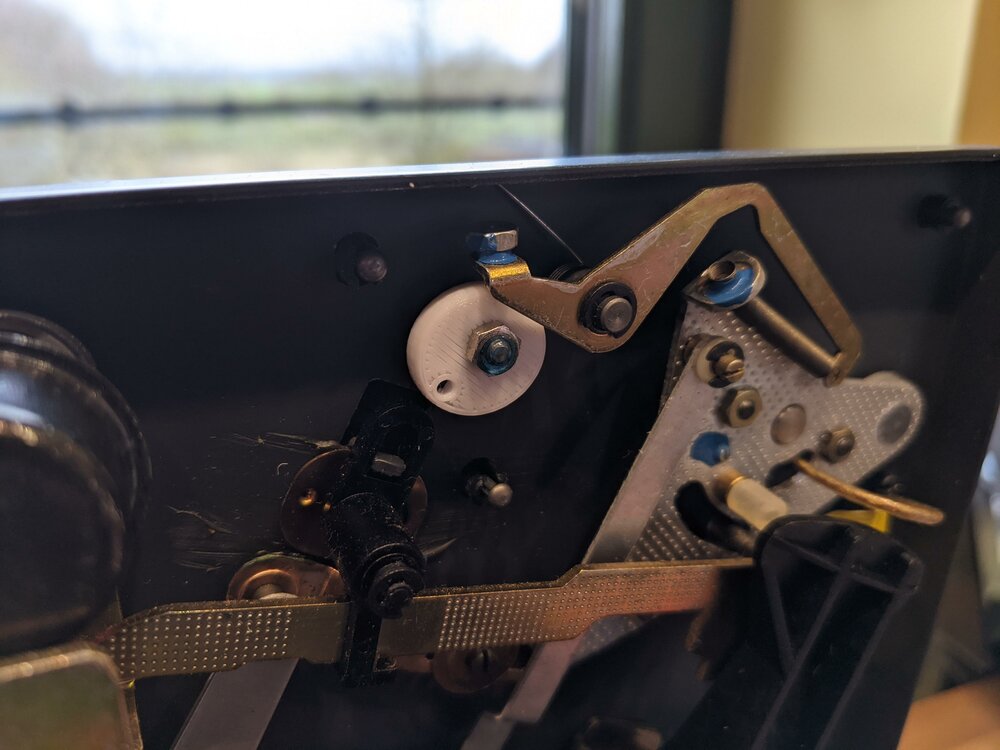

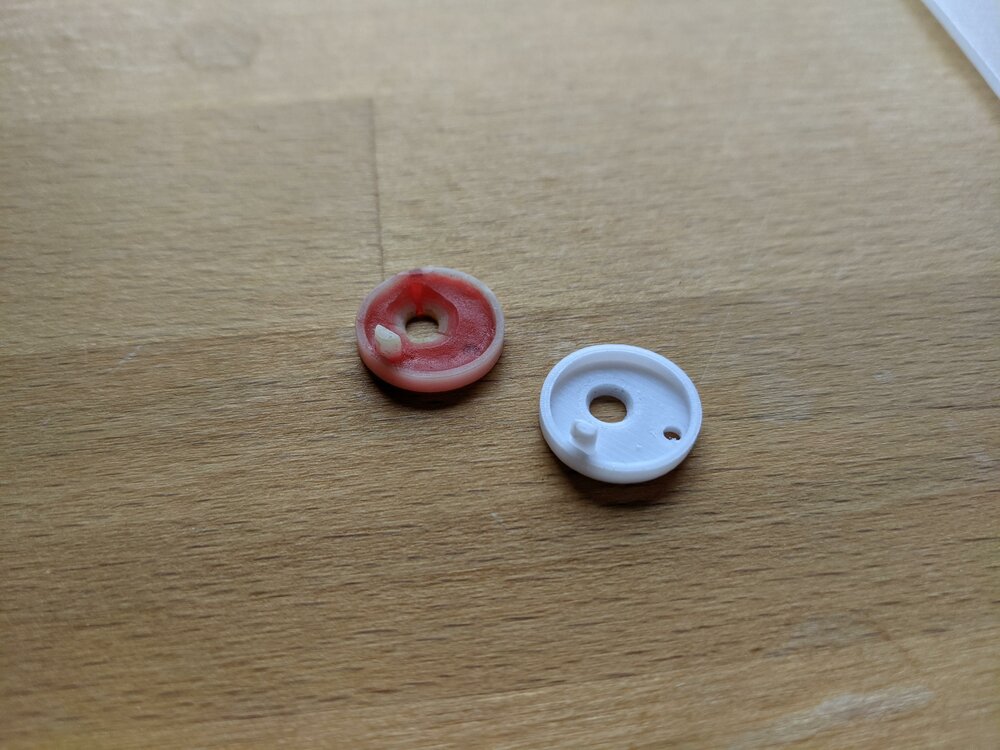

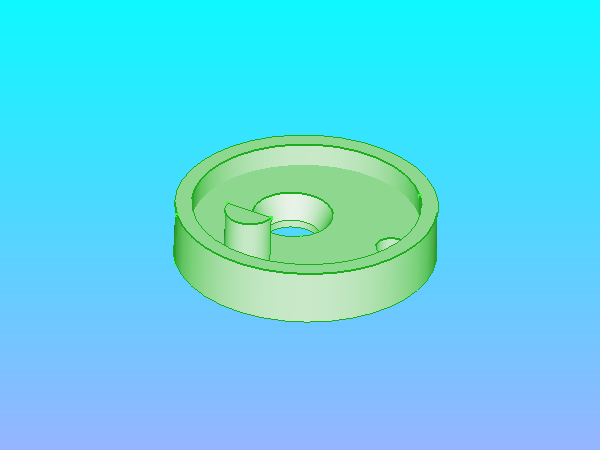

The “Kurvenrad”

The “Kurvenrad” is part of the anti skating functionality and is not so important for me, but it was cracked, so I want it to be replaced. I designed it in FreeCAD with approximate dimensions because it's really hard to measure (is a weird ellipsis with non-centered axis hole).

I tried to reinforce the original “Kurvenrad” (left) with red plastic before but it wasn't working well, so I printed a replacement part (right) with my new and amazing Prusa i3 MK3S+

I secured the “Kurvenrad” with some nail polish:

The height lever of the ton arm

Because the partly cracked part was hard to dismount, I did not design a 3D printed replacement, but simply added some aluminium around it and applied some super glue:

The knob indicators

One of the front knob indicators was broken and also the other existing ones complicated the cleaning/polishing process of the aluminium knobs. So I designed 3D printed replacement parts which was really easy because of the trivial shape. The result looks stunning (the original ones were black, but I prefer white ones):

Gallery

Here you can see some more pictures of the finished result: